Our Products

CP nozzle division of Transland manufactures a variety of Aerial Nozzles to fit any Aerial Application needs best. CP aerial nozzles are easy to use and easy to maintain. The multiple orifice options on all CP nozzles keep applicators working with minimum time spent changing nozzles.

CP brings the same trusted technology that serves over 90% of aerial applicators to the Ground Spray Nozzles. The ground nozzles are multi orifice/deflection nozzles with an easy carousel turn type function that keeps applicators working with minimum time spent changing tips.

The HiTek Rotary nozzle is an excellent Insecticide/fungicide nozzle addition to Transland’s nozzle line. It continues to be a great low-volume rotary nozzle used in AG and forestry worldwide.

The Accu-Flo Radial nozzle is a uniquely designed spray nozzle that provides Superior Drift Control for Helicopters. Applies as precise as a paintbrush, this distinctive nozzle is used in AG, Forestry, and right-of-way work around the globe.

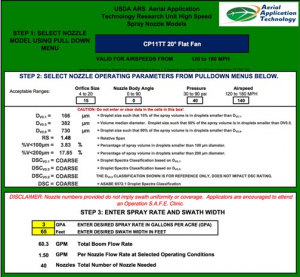

USDA Models

Once an Orifice/Tip size is determined, enter the information into the USDA-ARS Atomization models to view droplet spectrum data. Models are available in Low Speed (115mph Below) and High Speed (120mph above).

Calculation Tools

Quick Calc

Narrow down the nozzle options using the CP Quick Calibration tool. This will filter all known settings and show a suggested Orifice/Tip size with an estimated pressure for use. All pressure settings that fall between 30-60psi will be shown.

1206 Hatton Rd Suite A, Wichita Falls, Tx 76302

Phone (800) 388-2511

Fax (940) 687-1941